TrakSYS

The platform for production operations management and optimization

Portada » TraKSYS

TrakSYS

One platform. Multiple solutions.

TrakSYS is a unified platform with multiple fully integrated features. TrakSYS makes a difference in the way efficient, fast and cost-effective solutions can be created, implemented and maintained.

asm Soft

Parsec Certified Partner

TrakSYS is a development platform and therefore, to successfully carry out a project tailored to customer needs, it is essential to have an experienced partner. In ASM we have more than 10 years of experience with TrakSYS and we have carried out more than 20 projects in different sectors.

Quality

Quality

Performance

Performance

E-Records

E-Records

TrakSYS

Real-time plant data

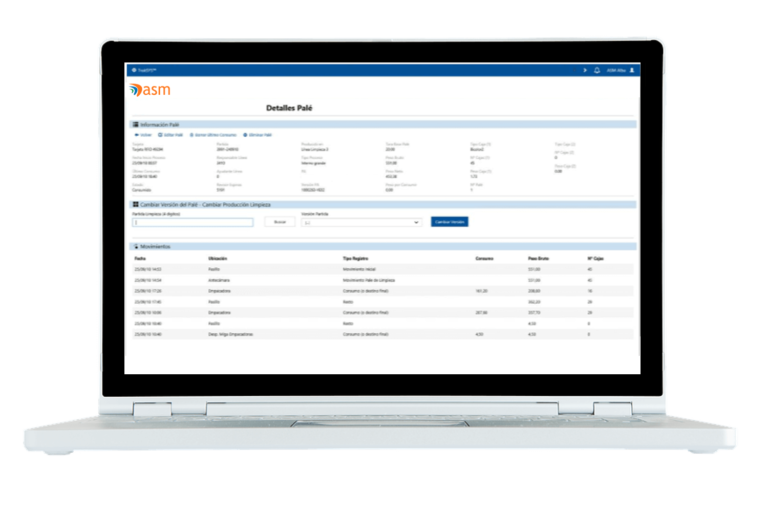

TrakSYS is a platform that collects and stores in real time all the information of the production process from raw material input, manufacturing operations, to finished product output: Traceability, quantities consumed and produced, batches, personnel, operating times, water and energy consumption, process variables, quality control, batch and regulatory compliance (EBR).

Traceability

Traceability

Batch Processes

Personnel in position

Energy

Functionality

One platform. Multiple solutions.

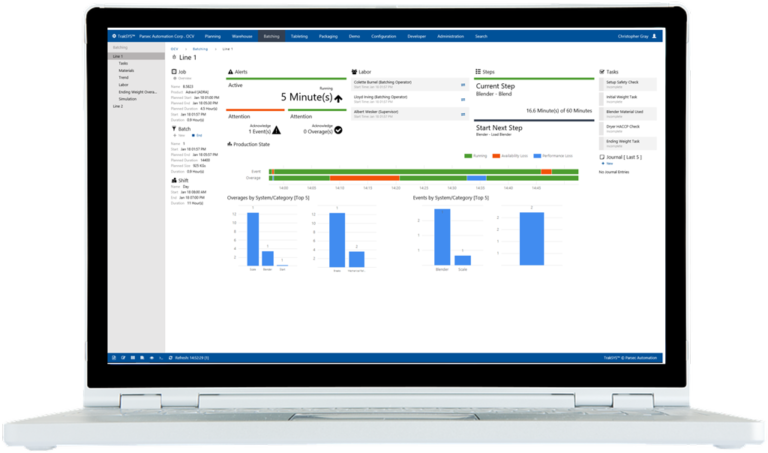

Performance

Production efficiency. OEE.

Productivity. Planned, no-load and unplanned stops, breakdowns, etc. Efficiency by equipment, line and total plant according to OEE metrics. Productivity KPIs (D, R, Q, OEE, SEEP, TEEP, MTBF, MTTR, etc.).

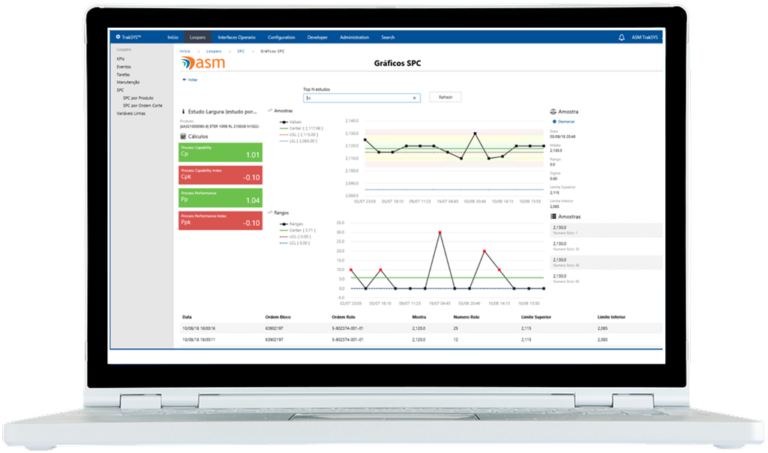

Quality

Quality control. SPC

Quality Control tasks, calculation of averages, deviations, overdoses, shrinkage, etc. Statistical Process Control (SPC): Capacity, of any quality or process variable and Control Charts.

EBR

Electronic Batch Records

Electronic recording of process variables (temperatures, pressures…) associated to manufacturing batches. Controls of factory procedures. Step-by-step recipe execution and electronic signature. Step by step control of materials.

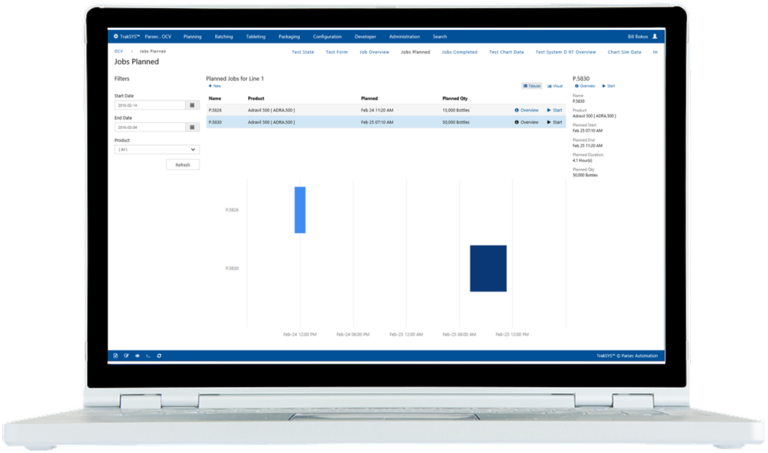

Planning & Scheduling

Quality control. SPC

Visual planning of manufacturing tasks. Estimated duration times based on productivity. Estimated order end time. Non-production windows for maintenance planning.

Batch Processing

Batch & Recipe

Control of batch processes such as cooking, fermentation… and electronic recording of associated variables (temperatures, pressures…). Step-by-step recipe controls according to factory procedures.

Energy & Sustainability

Visibility of energy consumption

Monitoring of electrical and thermal energy consumption. Integration with generation systems. Control of water and compressed air consumption. Calculation of energy consumption KPI per manufactured unit.

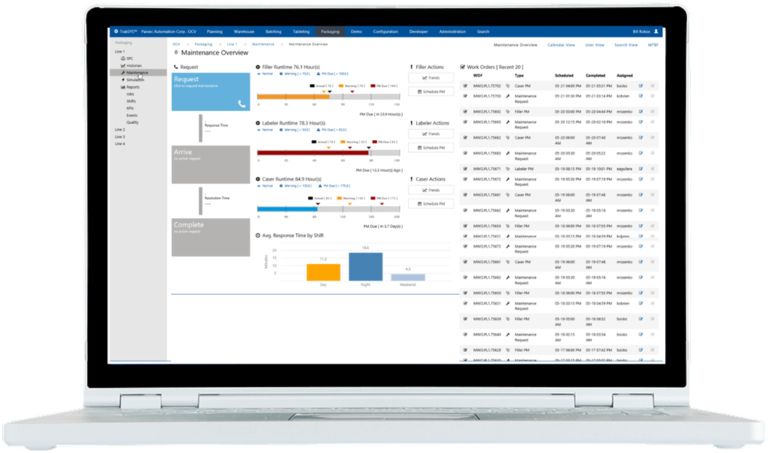

Maintenance

Maintenance tasks execution

Control of maintenance execution. Automatic alerts to maintenance when failures are detected. Control of response, repair and start-up times. Validation of technical causes of shutdowns.

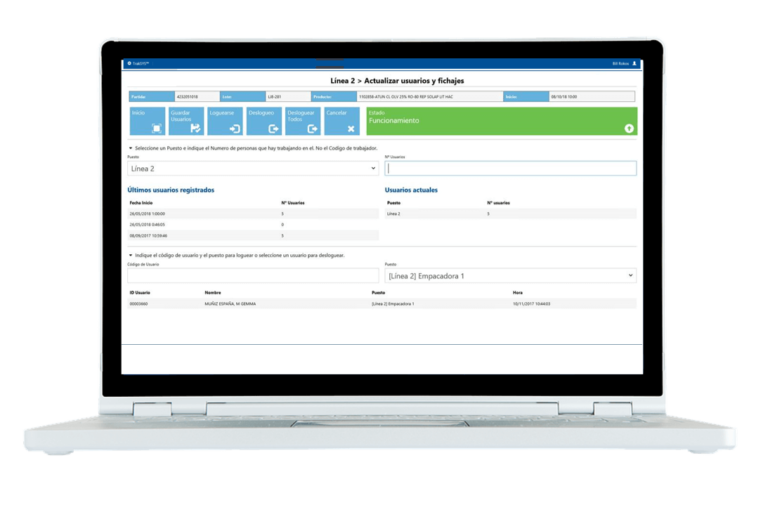

Labor

Personnel control at the workstation

Operator registration at the work station. Control of effective hours by manufacturing order. Records and traceability of the operations performed in each position. Management of training, polyvalence and limitations of the personnel for each position.

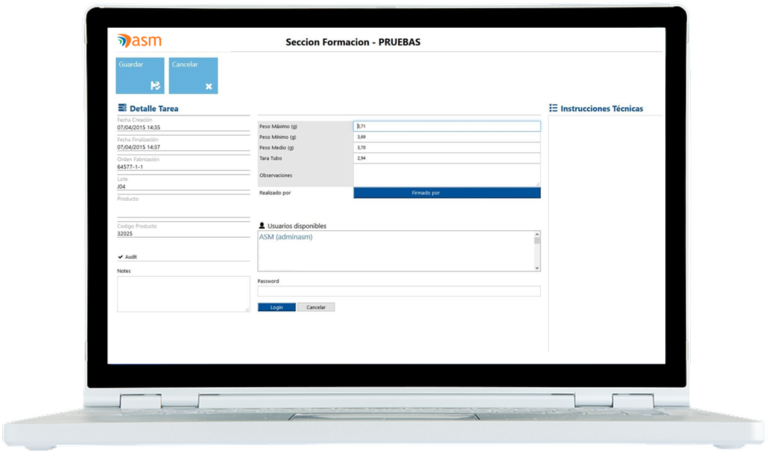

Weighing & Dispensing

Verification of weights and recipes

Weighing control of raw materials. Automatic connection to scales. Verification of quantities according to recipes. Weight ranges and alerts in case of deviations. Mixing control..

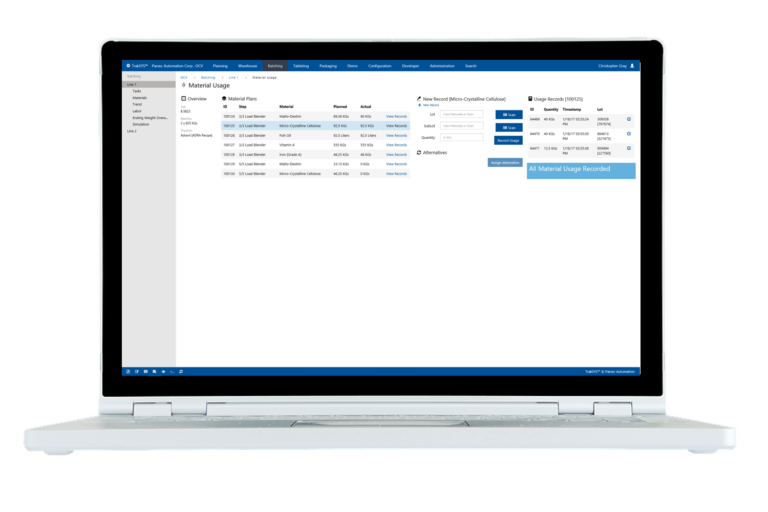

Material Management

Traceability and consumption

Control of materials in the plant, location, destination orders, movements and consumption. Integration with RFID systems for digital registration of all movements.

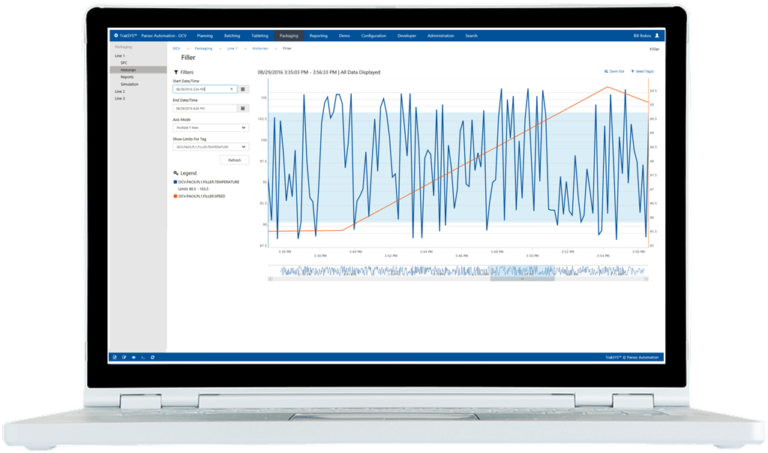

Historian

Variable monitoring

Monitoring of any type of variable. Historical records of temperature, humidity, pressures… Historical analysis of trends and correlations with other variables.

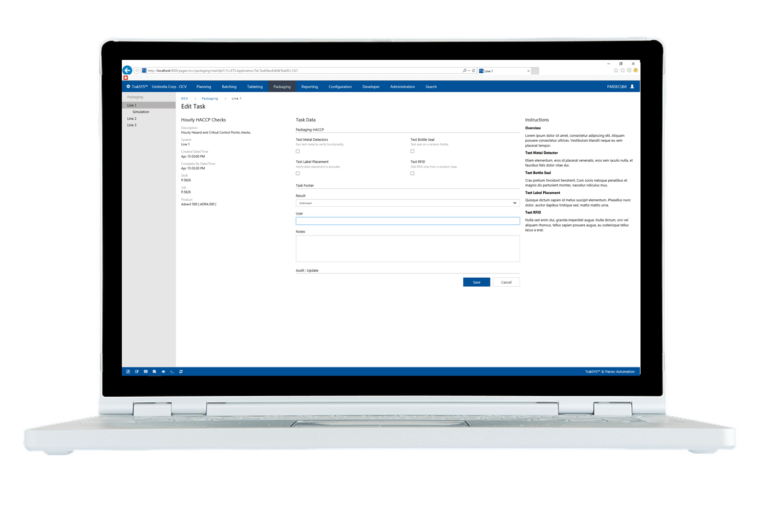

Task Management

Task Management

Task management can be applied to in-process controls, quality controls, machine cleaning verification processes or for maintenance orders. The task structure is flexible to adapt to all circumstances.

Messaging & Notification

Messaging & Notification

Alerts and notifications system when a variable goes out of the established limits, a certain event occurs or any combination is fulfilled. Sending SMS or Email to defined users. Pyramidal structure that allows to manage different alert levels and relate them to different users.

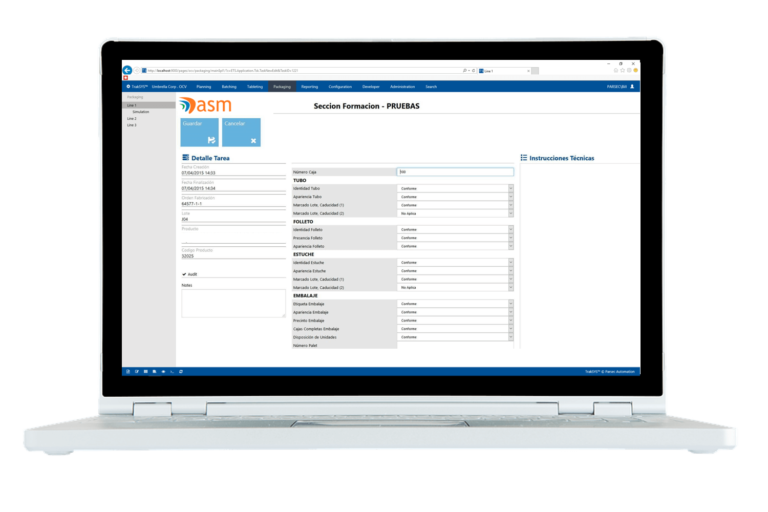

Electronic Forms

The paperless plant

Electronic forms can replace manual sheets. Any type of data can be collected in TrakSYS interfaces and integrated with other systems to which plant personnel do not have access.

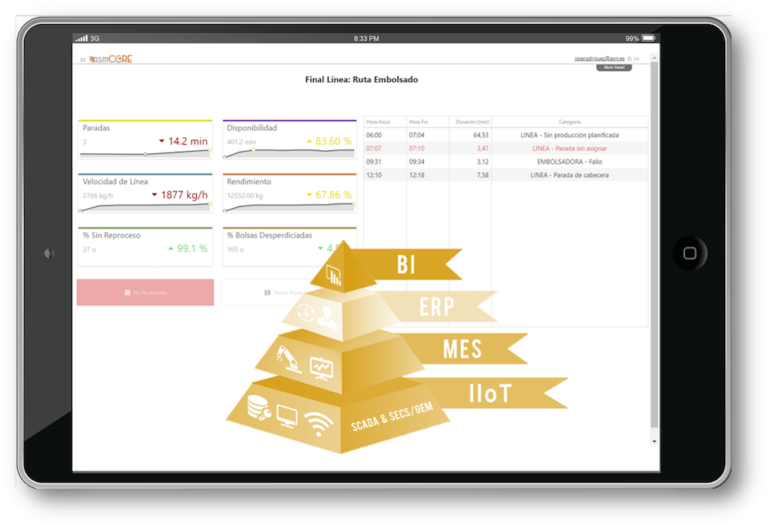

Manufacturing Intelligence

Intelligence for decision making

Dynamic analysis, in real time or historical, of all plant information. Intuitively analyze the data to obtain the causes that reduce productivity. Downloadable PDF reports.

Enterprise Visibility

Company overview

A global and unified view of the status of the group’s different production plants or the different manufacturing lines of a facility. A global vision oriented to management levels, but allowing to navigate to the detail when a deviation is detected.

ERP Integration

Data integrity

The integration with the ERP is bidirectional. The platform will collect the information of the pending manufacturing orders, to be executed in the plant. Once completed, it will report all the data on units manufactured, operation times, personnel and consumption for cost calculation.

Resources

Product Guide

TrakSYS Guide

Platform for production operations management and optimization

TrakSYS is a platform that collects and stores in real time all the information of the production process from raw material input, manufacturing operations, to finished product output.

Download the guide here.

Access the PDF document and you will receive a copy in your e-mail.

Clients

Companies that trust asm and TrakSYS

Contact

Request a free product demo

FEDER

FEDER